Tribupneu Explained: Benefits, Applications & Future Use

Introduction to Tribupneu

Tribupneu is revolutionizing how modern systems handle motion, friction, and energy efficiency. At its core, Tribupneu combines pneumatic technology with tribology the science of friction, wear, and lubrication, to create smoother, safer, and more durable operations. Unlike traditional mechanical setups, Tribupneu actively manages contact surfaces and airflow, reducing unnecessary resistance and wear. This approach not only extends system life but also lowers energy consumption and maintenance costs. Today, industries from manufacturing to robotics are turning to Tribupneu for smarter, quieter, and more reliable performance, making it a game-changer in modern engineering.

History and Origin of Tribupneu

The term Tribupneu comes from ‘tribology,’ which is the science of friction, combined with ‘pneu,’ referring to pneumatic systems. The concept emerged from the need to improve traditional pneumatic mechanisms that often faced energy losses and high maintenance. Over time, engineers realized that integrating friction management with controlled air pressure could optimize performance. This hybrid approach was first explored in high-precision manufacturing but quickly expanded into robotics, logistics, and energy systems. Tribupneu represents a modern evolution in motion control, showing how a blend of old concepts with new technology can redefine system efficiency, safety, and reliability in real-world applications.

Meaning of “Tribo” and “Pneu”

“Tribo” comes from the Greek word for friction, while “pneu” refers to air or gas-based systems. Together, Tribupneu emphasizes controlled interaction between surfaces and pneumatic support. This combination allows machinery to operate more efficiently, reduce wear, and maintain stability under varying loads. By actively managing friction rather than letting it occur naturally, Tribupneu creates a smarter, energy-conscious system that outperforms traditional setups, especially in demanding industrial environments.

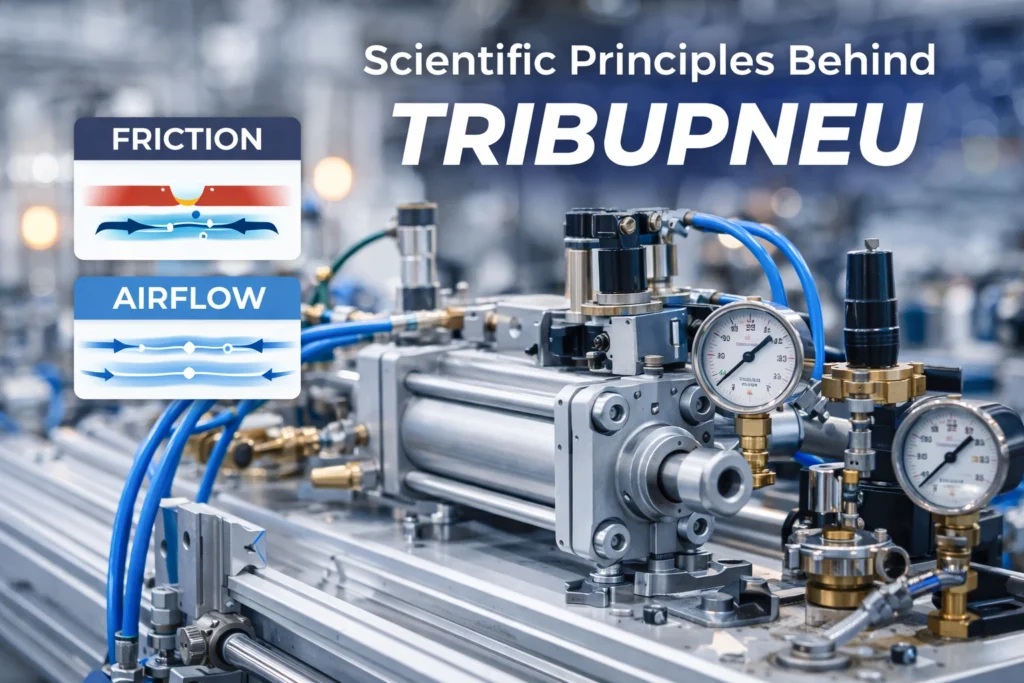

Scientific Principles Behind Tribupneu

Tribupneu operates on the principle of balancing friction, airflow, and surface interaction to maximize efficiency. It creates a thin, controlled pneumatic layer between moving surfaces, reducing direct contact and heat buildup. By optimizing how surfaces interact, energy is conserved, vibrations are minimized, and wear is significantly reduced. Adaptive mechanisms respond to changes in speed, load, or environmental conditions, ensuring consistent performance. This scientifically grounded approach sets Tribupneu apart from conventional systems, offering smoother operation, longer component life, and reduced maintenance costs. Its principles make it ideal for industries seeking smarter, more sustainable solutions.

👉 You might also like: Prizmatem Complete Guide 2026

How Tribupneu Works

Tribupneu systems form an air-managed interface between moving components, preventing excessive friction while maintaining stability. Controlled air pressure ensures a consistent cushion, while surface designs enhance airflow efficiency. Adaptive responses adjust to operational demands, including varying speeds, loads, and temperatures. This dynamic balance allows components to move freely yet remain supported, reducing energy loss and mechanical stress. The result is smoother, quieter, and longer-lasting operation. By integrating tribology and pneumatics, Tribupneu ensures systems run smarter, not harder, improving both productivity and reliability across manufacturing, robotics, and transportation sectors.

Key Components of Tribupneu Systems

Tribupneu systems rely on a combination of carefully engineered components that work in harmony to manage friction and airflow. Core elements include pneumatic actuators, precision valves, and adaptive sensors that monitor load, pressure, and temperature. Specialized surface coatings and materials minimize wear and ensure smooth operation under high stress. Together, these components create a self-regulating system that optimizes energy use, reduces vibration, and extends lifespan. Each part is designed to interact seamlessly, making Tribupneu systems highly reliable and suitable for complex industrial applications, from automated production lines to advanced robotics.

Pneumatic Actuators and Valves

Pneumatic actuators and valves control airflow and pressure, providing the necessary force and movement for Tribupneu systems. By precisely regulating air, these components reduce friction between surfaces while maintaining stability. This ensures smoother motion, lower energy consumption, and longer component life. Their efficiency is critical to the system’s overall performance, allowing Tribupneu to outperform traditional pneumatic setups in both speed and durability.

Sensors and Automation Modules

Sensors in Tribupneu systems monitor real-time conditions like pressure, load, and temperature. Automation modules adjust airflow and surface interactions accordingly. This adaptive control minimizes wear, prevents overheating, and keeps the system running efficiently. The integration of smart sensors makes Tribupneu ideal for industries that demand precision, reliability, and minimal downtime, from robotics to transportation.

Tribupneu vs Traditional Pneumatic Systems

Tribupneu significantly improves upon traditional pneumatic systems by integrating friction management directly into its design. Standard pneumatic systems rely mainly on pressurized air to move components, often resulting in energy loss, vibrations, and wear over time. Tribupneu adds a friction-optimizing layer, reducing surface contact and conserving energy. This results in smoother operation, quieter performance, and longer system life. Businesses benefit from lower maintenance costs and fewer breakdowns. In essence, Tribupneu represents a smarter, more sustainable evolution of pneumatics, combining efficiency and durability for modern industrial and robotic applications.

Industrial Applications of Tribupneu

Tribupneu has found widespread adoption across industries that demand precision, efficiency, and durability. In manufacturing, it optimizes automated assembly lines, reducing wear on moving parts and cutting energy costs. Robotics benefits from smoother, quieter motion and better load handling, while transportation systems use Tribupneu for controlled movement in pneumatic-assisted components. Material handling equipment, packaging lines, and energy-efficient machinery also gain performance advantages. Its ability to adapt to changing loads and environmental conditions makes Tribupneu highly versatile, ensuring reliable operation in diverse industrial scenarios while reducing maintenance and operational costs.

Energy Efficiency and Sustainability Benefits

One of the most compelling advantages of Tribupneu is its energy efficiency. By reducing friction and optimizing airflow, Tribupneu systems consume less power than conventional pneumatic systems. This results in considerable savings on energy costs while also reducing environmental impact. Additionally, reduced wear extends component life, lowering waste and resource consumption. Industries focused on sustainability and operational efficiency are increasingly adopting Tribupneu to meet environmental standards while maintaining productivity. The technology aligns with modern goals of energy-conscious engineering, combining smarter motion control with eco-friendly practices.

Maintenance Tips for Tribupneu Systems

Proper maintenance is crucial for maximizing the lifespan and efficiency of Tribupneu systems. Regular inspections of pneumatic components, sensors, and surface coatings help detect wear early. Cleaning and lubrication prevent unnecessary friction, while monitoring air pressure ensures consistent performance. Scheduled system checks can prevent costly downtime and maintain smooth, energy-efficient operation. Following manufacturer guidelines and employing predictive maintenance strategies further enhances reliability. By investing in routine care, businesses not only protect their equipment but also optimize performance, reduce operational costs, and ensure the system continues delivering precision and durability over the long term.

Safety and Reliability Considerations

Safety is a core advantage of Tribupneu technology. By reducing friction and vibration, the system minimizes the risk of mechanical failure and operator injury. Built-in sensors and adaptive controls ensure components operate within safe limits, even under varying loads or environmental conditions. Reliability is enhanced through redundant monitoring, alerting operators to potential issues before they escalate. These features make Tribupneu suitable for high-precision and high-risk industrial applications. Companies adopting this technology benefit from fewer accidents, lower liability risks, and confidence in consistent, safe operation across complex production and robotic systems.

Challenges in Implementing Tribupneu

While Tribupneu offers numerous benefits, implementing it can present challenges. Initial costs may be higher than traditional pneumatic setups due to specialized components and smart sensors. Technical expertise is required for proper installation and calibration to maximize system efficiency. Environmental factors like extreme temperatures or dust can affect performance if not properly managed. Additionally, integrating Tribupneu into legacy systems may require design adjustments. However, these challenges are typically offset by long-term energy savings, reduced maintenance costs, and improved operational reliability. Careful planning and skilled installation are key to successful implementation.

Real-World Case Studies of Tribupneu

Tribupneu has proven its value across multiple industries through practical implementation.

👉 You might also like: Exploring the Future of Technology

Manufacturing Success Stories

Automated assembly lines using Tribupneu report lower component wear and reduced energy consumption. Companies experience fewer machine stoppages, improving productivity and reducing operational costs significantly.

Transport & Logistics Examples

In material handling and logistics, Tribupneu enhances pneumatic lifts and conveyors. Smooth motion control reduces mechanical stress, leading to longer equipment life and consistent performance, even under heavy loads.

Future Trends and Innovations in Tribupneu

Tribupneu technology is evolving rapidly, integrating AI, predictive maintenance, and smart IoT sensors. Future systems may self-optimize airflow and friction in real time, responding to load, speed, and environmental changes automatically. This will further reduce energy usage and maintenance needs. As Industry 4.0 expands, Tribupneu is poised to become a core technology in robotics, automated production lines, and green energy systems. Its potential to improve efficiency, safety, and sustainability makes it a crucial part of the next generation of industrial innovation, positioning companies for competitive advantage.

Common Misconceptions About Tribupneu

Many assume Tribupneu is just another pneumatic system, but it is far more advanced. Unlike traditional systems, it actively manages friction and surface interactions, which improves efficiency and lifespan. Some think it’s only for high-end robotics, yet it benefits a wide range of industries, from manufacturing to logistics. Another misconception is that maintenance is more complex; in reality, routine inspections and sensor-based monitoring simplify care. Understanding the true capabilities of Tribupneu ensures companies can fully leverage its energy savings, operational reliability, and sustainable performance.

Conclusion

Tribupneu represents a leap forward in pneumatic and motion-control technology. By integrating friction management, smart sensors, and airflow optimization, it delivers smoother, safer, and more energy-efficient operation. Industries adopting Tribupneu benefit from reduced maintenance, lower energy costs, and improved system reliability. Its versatility, sustainability, and potential for future innovations make it a vital solution for modern engineering challenges. In short, Tribupneu is not just a technology upgrade; it’s a strategic investment in smarter, more durable, and environmentally conscious industrial operations.

Frequently Asked Questions (FAQs)

What is Tribupneu?

Tribupneu is an advanced technology that combines pneumatics with tribology—the study of friction and wear. It creates smoother motion by reducing surface contact and optimizing airflow, making machines more efficient, quieter, and longer-lasting.

How does Tribupneu work?

Tribupneu forms a controlled air layer between moving components, reducing friction and wear. Sensors and adaptive controls adjust airflow and surface interactions in real time, ensuring consistent performance even under heavy loads.

What industries use Tribupneu?

Tribupneu is widely used in manufacturing, robotics, logistics, material handling, and transportation systems. Any industry that relies on pneumatic systems or precise motion control can benefit from its efficiency and durability.

How is Tribupneu different from traditional pneumatic systems?

Unlike standard pneumatic setups, Tribupneu actively manages friction and surface interactions. This reduces energy consumption, vibrations, and maintenance while extending system lifespan. It’s a smarter, more sustainable solution for modern engineering.

Is Tribupneu expensive to implement?

Initial costs may be higher due to specialized components and sensors. However, long-term energy savings, reduced maintenance, and increased system reliability typically outweigh the upfront investment, making it cost-effective over time.

How often should Tribupneu systems be maintained?

Regular inspections, cleaning, and monitoring of sensors and actuators are recommended. Routine checks help detect wear early, ensure consistent airflow, and maximize energy efficiency, minimizing unexpected downtime.

Can Tribupneu improve energy efficiency?

Yes! By reducing friction and optimizing airflow, Tribupneu consumes less energy compared to conventional pneumatic systems. This not only cuts costs but also lowers the carbon footprint of industrial operations.

Are Tribupneu systems safe to operate?

Absolutely. Built-in sensors, adaptive controls, and reduced vibrations make Tribupneu systems safer for operators and machinery, even under high loads or variable environmental conditions.

Can Tribupneu be integrated into existing machinery?

Yes, but careful planning is required. Legacy systems may need adjustments to accommodate Tribupneu components, including sensors and actuators, to ensure optimal performance and compatibility.

What is the future of Tribupneu technology?

Tribupneu is evolving with AI, IoT, and predictive maintenance, enabling systems to self-optimize in real time. Its future lies in Industry 4.0 applications, robotics, and energy-efficient manufacturing, offering smarter, sustainable, and reliable operations.

✨ Good read? Better ones are coming, follow Dympigal